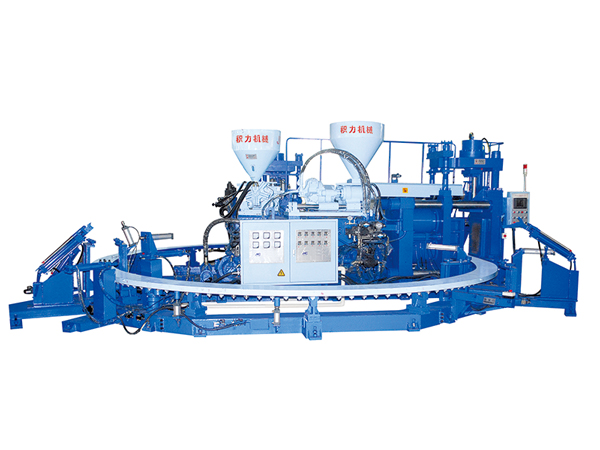

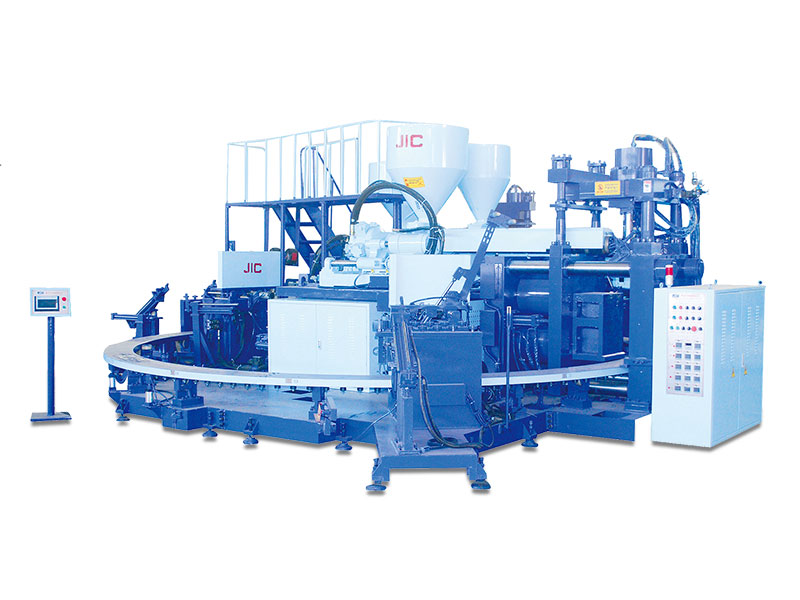

One Color EVA Injection Molding Machine

Automatic linear injection machine for producing EVA soles, sandals, slippers and boots

Material: EVA

Applications

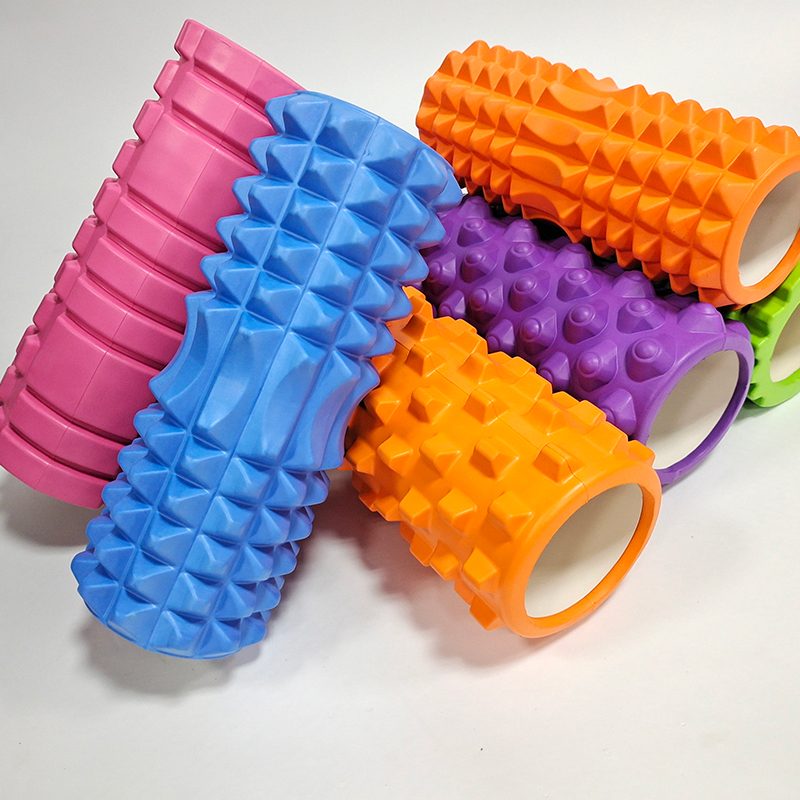

One-color EVA soles of sneaker, slippers, sandals, boots, sport equipment, toys, bags, cases and other products.

One-color EVA injection molding machine is widely used to produce EVA soles, sandals, slippers and boots.

Besides the standard molds that are 290*550mm, we also provide customized mold dimensions, such as, 305*550mm and 330*600mm, along with stronger clamping force and enlarged mold opening strokes to enable all manual operations like collecting products in advance, cleaning molds and adding release agent. Large sizes of screw and barrel, such as, 65mm, 70mm and 75mm, are also provided to produce larger EVA products, such as, high boots, wheels and anti-collision poles.

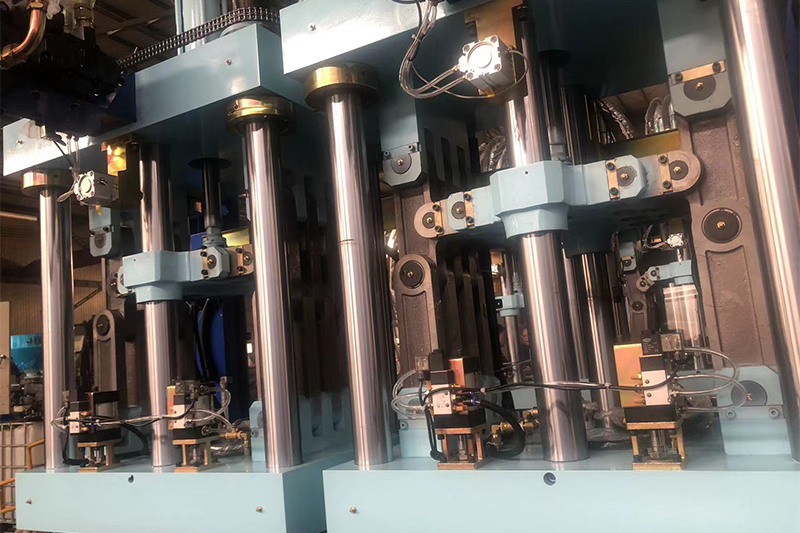

- 2 molds in one station work independently, which greatly improves productivity;

- Self-compensating mold plates ensure high-quality products;

- Mold opening is quick thanks to the structure consisting of crank and connecting rod;

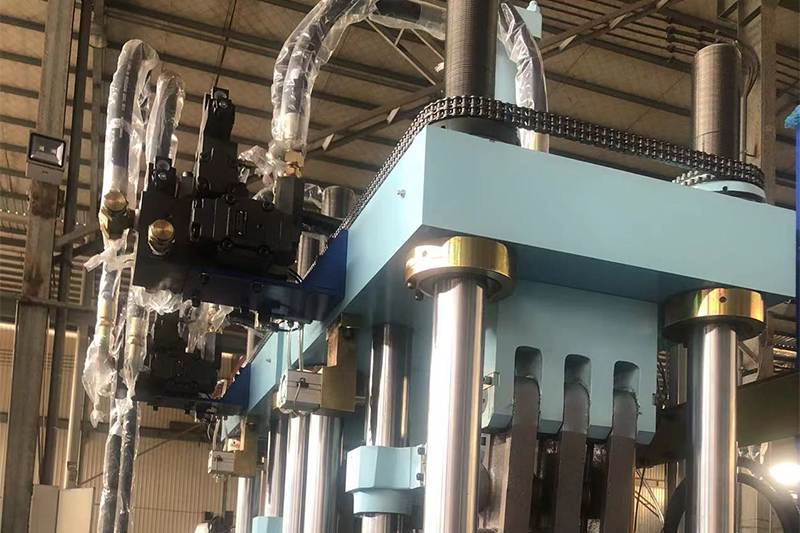

- The servo hydraulic unit saves 50% of electricity;

- Customized molds are provided to meet various production demands;

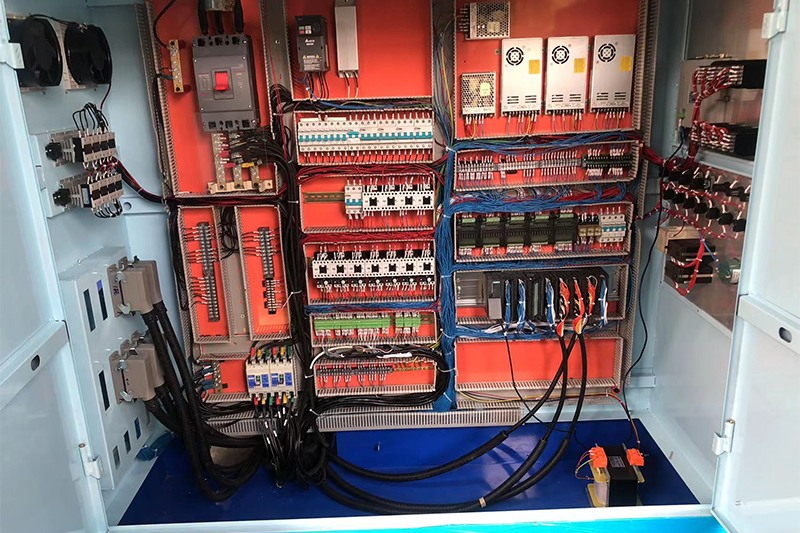

- The electronic control system adopts Siemens CPU which runs efficiently.

| Item | Unit | Specifications | ||

| Model | | | | |

| Raw material | EVA | EVA | EVA | |

| Number of station | 2 | 6 | 8 | |

| Clamping force | T | 180 | 180 | 180 |

| Mold opening stroke | mm | 350 | 350 | 350 |

| Mold size | mm | 290*550 | 290*550 | 290*550 |

| Mold height | mm | 100-260 | 100-260 | 100-260 |

| Screw diameter | mm | Ø60 | Ø60*2 | Ø60*2 |

| Screw rotational speed | rpm | 0-165 | 0-165 | 0-165 |

| Max. injection volume | cm3/cc | 930 | 930*2 | 930*2 |

| Injection pressure | kg/cm2 | 1080 | 1080 | 1080 |

| Temperature setting | stage | 4 | 4 | 4 |

| Heating power (feed hopper) | kW | 6 | 6*2 | 6*2 |

| Heating power (mold) | kW | 25.6 | 76.8 | 102.4 |

| Hydraulic motor | kW | 37/32 | 55/50 | 55/50 |

| Total power | kW | 62/57 | 131/126 | 157/152 |

| Oil consumption | kg | 800 | 1000 | 1000 |

| Machine dimensions | mm | 4680*4600*2875 | 8230*3800*2875 | 10650*4800*2875 |

| Gross weight | kg | 11000 | 26000 | 33000 |

- Injection unit The injection unit is equipped with the measurement system consisting of a potentiometer detector, a PLC and PC computing to precisely control the injection volume. The frequency converter along with a linear slide and a speed reducer enables smooth and quick movement of the injection unit. The rotary encoder is used for detection and positioning.

- Molding closing system The two-stage mold opening and closing system is equipped with a detector to make sure the mold is completely closed. Large mold opening stroke offers high flexibility for different molds.

- Control system The control system adopts a graphical interface and a touchscreen. A PLC modular design in the Windows system is clear to identify functions and easy to learn operation. The system provides the function of online monitoring of rotational speed of material feeding, injection volume, time and temperature, sulfur adding time and productivity. The user-friendly control system enables easy and convenient operation.

- Hydraulic system The dual-ratio control valve along with the control system can precisely control pressure and rate of multiple hydraulic flows.

- Energy-saving design High-quality thermal insulation panels in each station preserve heat without use of water.

- Low operation table The low operation table is an ergonomic design to increase operators’ efficiency and productivity.

- Flexible adjustment of the mold opening stroke Mold opening stroke can be adjusted freely within a range of 100-260mm.

We can produce shoe making machines based on clients’ requirements, such as, dimensions, specifications, voltage and colors. We also provide voltage-compatible motor.

The major advantages of servomotor lie in saving energy, less noise, and better stability during operation at low oil temperature, which results in prolonged service life of oil seal.

A4 PVC air blowing is a mature technology that adopts chemical blowing agents to make shoes that feature lightweight, better airflow, slip resistance and durability. Shoes produced in an air blowing process are more comfortable to wear and thus they are popular in the market.

Our footwear machines are highly automated and maneuverable. One or two workers can easily handle the operation of machines.

We provide the PVC rain boot making machine with a robotic arm that is able to automatically remove flash, open and close molds. The robotic arm thus largely reduces workload and improves productivity.

Ancillary machines are provided to improve the productivity of shoe making machine.