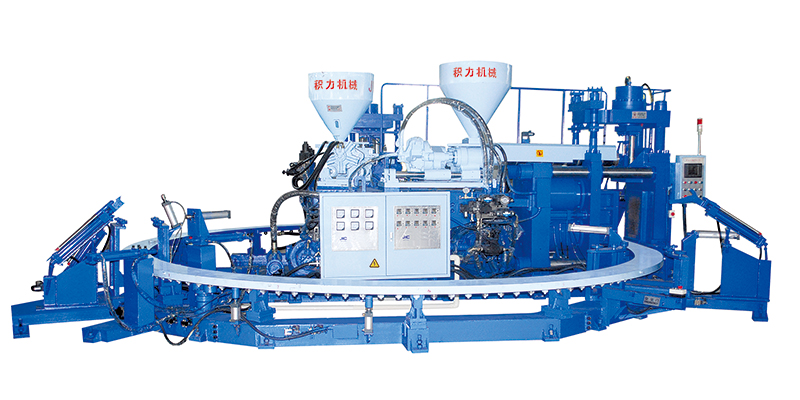

Two Color PVC Rain Boot Injection Molding Machine

Rotary injection molding machine for producing plastic rain boots

- The clamping force is balanced to stabilize product quality;

- It is easy and convenient to install and detach molds;

- Servo hydraulic system generates energy efficiently as it saves 40% of electricity;

- The injection molding machine features high productivity as it is able to produce 90-100 pairs of shoes within one hour;

- The robotic arm that is able to automatically remove flash is optional.

Material: PVC

Technical Specifications

| Item | Unit | Parameters | ||

| Model |

|

|

|

|

| Raw material | PVC | PVC | PVC | |

| Number of stations | 12 | 14 | 16 | |

| Max. injection volume | cm³/cc | 1270/770 | 1270/770 | 1270/770 |

| Rated injection pressure | kg/cm² | 0-150,0-120 | 0-150,0-120 | 0-150,0-120 |

| Power of electric heating | kW | 15+13 | 15+13 | 15+13 |

| Temperature setting | stage | 5 | 5 | 5 |

| Screw rotational speed | RPM | 0-150 | 0-150 | 0-150 |

| Screw diameter | mm | Ø90, Ø70 | Ø90, Ø70 | Ø95, Ø75 |

| Motor power | kW | 22,15 | 22,18.5 | 22,18.5 |

| Clamping force | T | 250 | 250 | 250 |

| Max. mold size | mm | 680*420*200 | 680*420*200 | 680*420*200 |

| Machine dimensions | mm | 6350*5260*2460 | 6350*5600*2460 | 6850*6000*2460 |

| Gross weight | kg | 18700 | 19500 | 20000 |

| Item | Unit | Specifications | |

| Model |

|

|

|

| Raw material | PVC | PVC | |

| Number of stations | 12 | 14 | |

| Max. injection volume | cm³/cc | 660/330 | 770/565 |

| Rated injection pressure | kg/cm² | 0-120 | 0-120 |

| Power of electric heating | kW | 11+9 | 13+11 |

| Temperature setting | stage | 5 | 5 |

| Screw rotational speed | RPM | 0-150 | 0-150 |

| Screw diameter | mm | Ø65,Ø50 | Ø70,Ø60 |

| Motor power | kW | 15,11 | 18.5,15 |

| Clamping force | T | 120 | 120 |

| Max. mold size | mm | 460*350*180 | 460*350*180 |

| Dimensions | mm | 5160*4500*2120 | 6000*4800*2120 |

| Gross weight | kg | 13000 | 13500 |

| Item | Unit | Specifications | |

| Model | | | |

| Raw material | PVC | PVC | |

| Number of stations | 12 | 14 | |

| Max. injection volume | cm³/cc | 770/660 | 770/660 |

| Rated injection pressure | kg/cm² | 0-150, 0-120 | 0-150, 0-120 |

| Power of electric heating | kW | 13+11 | 13+11 |

| Temperature setting | stage | 5 | 5 |

| Screw rotational speed | RPM | 0-150 | 0-150 |

| Screw diameter | mm | Ø70,Ø65 | Ø70,Ø65 |

| Motor power | kW | 18.5,15 | 18.5,15 |

| Clamping force | T | 180 | 180 |

| Max. mold size | mm | 520*390*200 | 520*390*200 |

| Dimensions | mm | 6750*5210*2345 | 6360*4950*2345 |

| Gross weight | kg | 14300 | 15000 |

Features

- The injection molding machine is used to produce one-color and two-color PVC rain boots;

- The control system consists of an industrial interface, a PLC and a touch screen.

- The hydraulic system with the dual-ratio control valve enables independent adjustment of pressure and rate of flow to produce high-quality shoes;

- The shoe making machine adopts digital measurement to precisely control shoes quality;

- The operator-friendly panel design enables easy and convenient operation;

- Equipped with the robotic arm, the shoe making machine realizes fully automatic operation to save labor and improve efficiency;

- The servomotor achieves the same performance as the traditional motor while consuming less energy.

Optional

Ancillary machines are provided to improve the productivity of shoe making machine.

With years of experience in the footwear machinery industry, JIC has established itself as a leading manufacturer for shoe making machines in China. Backed by our team of experienced professionals who have long been engaged in the design and production of footwear manufacturing machinery, we are currently capable of supplying an extensive range of high performance injection molding machines for shoes making, such as rain boot making machine, slipper making machine, casual clog making machine, shoe sole making machine, upper strap making machine, as well as injection molding machine built for making other plastic or rubber items. If you have any questions or concerns about shoe machinery, please contact us today.

Get in Touch