JIC MACHINE is one of the leading footwear machine manufacturers in China, with the business scope covering shoe making machines, light curing resin 3D printer, shoe molds and other machines. Thanks to quality products and professional teams, we have seen our footwear making machines winning trust of clients at home and abroad.

JIC MACHINE was founded in 2008 and it is located in the “City of Shoe Making” –Jinjiang, Fujian, covering the floor area of more than 10,000 square meters and the building area of 9,000 square meters. JIC MACHINE’s success is mainly contributed to a strong team of professional engineers, technical personnel and advanced equipment. Years of experience and long-term hard work of JIC MACHINE team members set us apart from fierce competition.

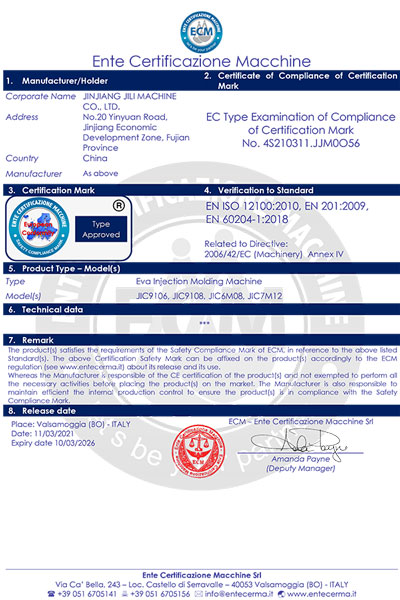

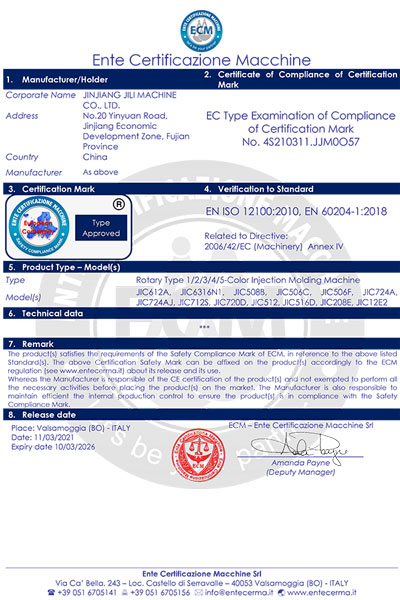

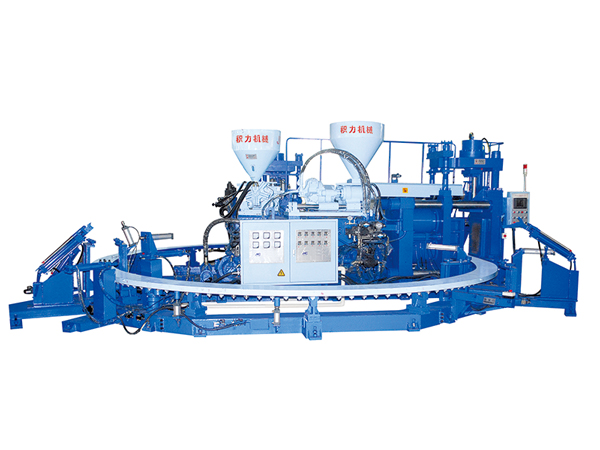

Since its establishment, JIC MACHINE has put innovation first as we always believe that innovation is the main reason why we achieve business success. We have independently innovated a series of shoe making machines, including PVC air blowing injection molding machines, patented three color rain boot making machines, three color slipper upper machines, one color/two color EVA injection molding machines (linear type), multi-color EVA compression molding machines, one color and two color EVA injection molding machine (rotary type), EVA secondary molding machines, two color/three color TPR sole making machines, rubber sole compression molding machines and 3D printers. Our 3D printers produced in cleanrooms have won trust of China’s leading footwear brand, Li-Ning, and entered the Brazil’s market.

By virtue of its outstanding products, JIC MACHINE has built partnership with local customers and foreign clients from Bangladesh, Pakistan, Indonesia, India, Vietnam, Russia, Argentina, South Africa, Malawi, Brazil, Colombia, Cameroon, Tanzania, Syria, Egypt and Turkey.

JIC MACHINE is a faithful and dependable partner for your successful business.

-

Experienced teams

JIC MACHINE boasts technical teams with 30-year experience. The technical engineer team is mainly made up of holders of master’s degree, doctoral degree and vocational certificates. After-sales personnel are competent to provide technical support in a professional way since they have experience in working abroad.

-

Quality material

We have stable and reliable suppliers to provide quality material. An independent department is particularly established to process material for various production requirements. Quality material ensures stable production of good footwear machines.

-

Advanced production lines

Complete production lines control high output quality. We have NC machine tools, CNC milling machines and drilling machines to control every fine detail.

-

1956Hubei Echeng Universal Machinery Group was established and later developed into the largest machinery manufacturer in the east Echeng city. It had cultivated numerous high-level engineers one of whom is the founder of JIC MACHINE. In the same year, the injection molding industry in China took off.

-

2010A new factory was built to expand business.

-

2011The company was renamed Jinjiang JIC Machine Company and registered the trademark “JIC”.

-

2012JIC MACHINE was moved to the Jinjiang Economic Development Zone and rolled out the unique JIC’s PVC air blowing injection molding machines, two color rain boot making machines and EVA injection molding machines.

-

2014-2019JIC MACHINE obtained patents for the self-developed machines one after another, for example, the automatic rain boot making machine with a robotic arm in 2014, the rain boot making machine with a robotic arm that enables automatic mold opening and closing in 2015, the EVA secondary molding machines in 2018, the movable scraper unit used in 3D printers and the photosensitive resin 3D printer with two stations in 2019.

-

2023After years of development, JIC MACHINE provides a complete range of shoe making machines, including PVC air blowing injection molding machines, two color rain boot machines, patent three color rain boot machines, 3/4/5/6 color slipper upper making machines, one color/two color EVA injection molding machines (linear type), multi-color EVA injection molding with a vacuum hood, 1/2 color EVA injection molding machines (rotary type), EVA secondary molding machines, , two color/three color TPR sole making machines, rubber sole compression molding machines and light curing resin 3D printers.

We actively participate in a variety of shoe making fair events to communicate with peer companies for technological exchanges and new information in the shoe making industry.