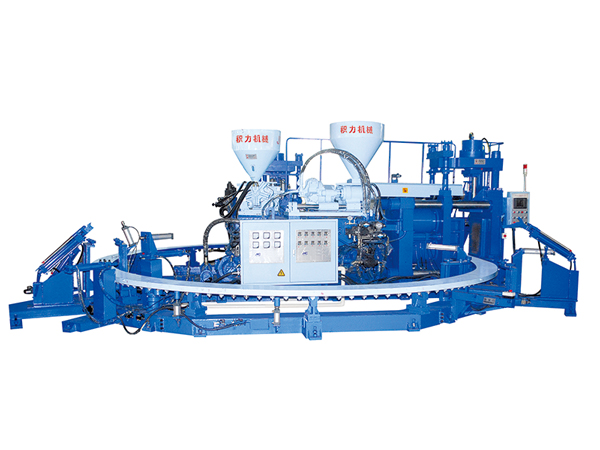

Multi-Color EVA Compression Molding Machine with Vacuum Hood

Footwear machinery for shoe sole making

- The EVA compression molding machine can be operated on one side or two sides, which increases productivity;

- Busch vacuum pumps ensure stable production and high-quality products;

- Two molds in one station work independently to double the productivity;

- Self-compensating mold plates contribute to high product quality.

Technical Specifications

| Item | Unit | Specifications | ||

| Raw material | EVA | EVA | EVA | |

| Number of stations | 6 | 8 | 10 | |

| Clamping force | mm | 180 | 180 | 180 |

| Mold opening stroke | mm | 350 | 350 | 350 |

| Mold size | mm | 600*330*2sets | 600*330*2sets | 600*330*2sets |

| Mold height | mm | 100-220 | 100-220 | 100-220 |

| Power of motor | kW | 16 | 16 | 16 |

| Power of heating | kW | 77 | 102 | 128 |

| Total power | kW | 93 | 118 | 144 |

| Oil consumption | kg | 600 | 600 | 600 |

| Machine dimensions | mm | 9560*1450*2950 | 11830*1450*2950 | 13850*1450*2950 |

| Gross weight | kg | 30000 | 39000 | 49000 |

Features

- The compression molding machine is mainly used to manufacture multi-color EVA foam products;

- The vacuum system ensures the molding process is clean and dust-free to produce high-quality products;

- The quality thermal insulation panels effectively preserve heat without use of water circulation;

- The compact structure reduces the occupation of floor space;

- The footwear machine is user-friendly as it is easy and convenient to operate;

- Servomotors and a PLC greatly improve efficiency and save energy.

Optional

Ancillary machines are provided to improve the productivity of shoe making machine.

With years of experience in the footwear machinery industry, JIC has established itself as a leading manufacturer for shoe making machines in China. Backed by our team of experienced professionals who have long been engaged in the design and production of footwear manufacturing machinery, we are currently capable of supplying an extensive range of high performance injection molding machines for shoes making, such as rain boot making machine, slipper making machine, casual clog making machine, shoe sole making machine, upper strap making machine, as well as injection molding machine built for making other plastic or rubber items. If you have any questions or concerns about shoe machinery, please contact us today.

Get in Touch